Application standard for automotive connectors

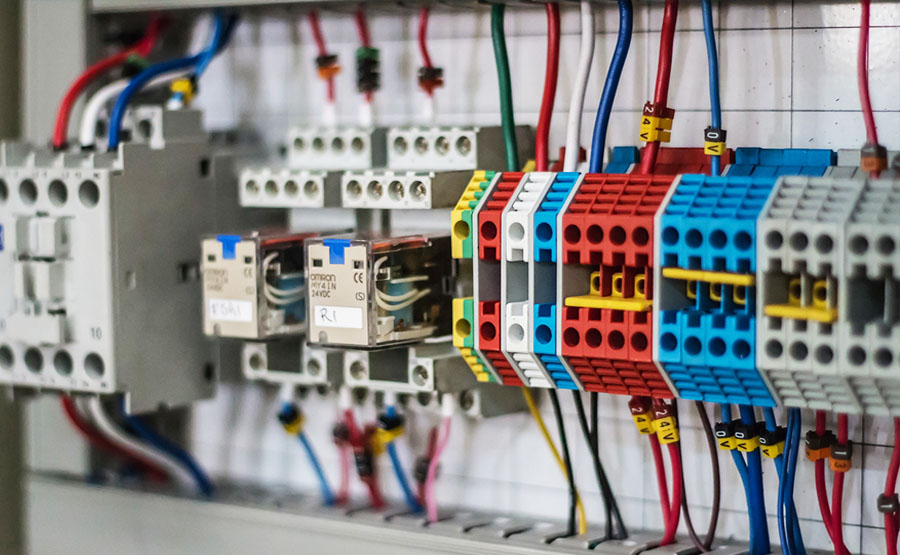

To meet the high performance requirements of energy vehicle connectors, it mainly depends on strict design specifications. For example, in case of exposure, it is necessary to prevent air breakdown by high voltage, which needs to reserve a certain air gap; Under the condition of high voltage and large current, the temperature rise shall not exceed the rated value; When selecting the shell material, we should consider the weight, strength and ease of processing, and how to maintain the stability of the material properties of the connector terminal at different temperatures and how to ensure the necessary conductivity.

In terms of connectivity, due to the continuous expansion of automotive entertainment system, the importance of high-speed data transmission function is becoming increasingly prominent. For example, on some models, the camera head is installed on the reversing mirror, which can enable the driver to have a wider field of vision, which requires the connector to transmit more data. Sometimes a connector is needed to solve the problem of transmitting GPS signal and broadcast signal at the same time, which needs to improve its data transmission capacity. At the same time, the connector also needs to withstand high temperature, because the car engine is usually placed in front of the car. Although there is a firewall for protection, some heat will be transmitted, so the connector should be able to withstand high temperature.